What Blades Do I Buy?

Posted by Vic Tesolin and MTC Staffers on 9th Jan 2024

Low angle planes are designed with the bevel of the blade facing upwards when installed on the bed of the plane. This bevel-up design offers you the option to choose between different blade cutting angles to suit the material and work at hand. This is a great advantage over traditional bevel-down hand planes where the downward facing bevel is only present to provide clearance for the cut to happen. But why would you want different angles?

Three blades to handle every challenge

The universal truth about woodworking is that wood is not a uniform material. Wood has grain. Long grain, short grain, quartered grain, end grain and cranky grain. Wood can also be hard or soft, stringy, or dense. The point is that wood is not uniform, so you need tools that can deal with the differing characteristics of woods. MTC offers three blades, each with a different cutting angle. These allow you to deal with the variations in wood and technique as required. A low 25° cutting angle for shaving end grain. A middle of the road 38° for general work. And a high angle of 50° for figured or cranky timbers.

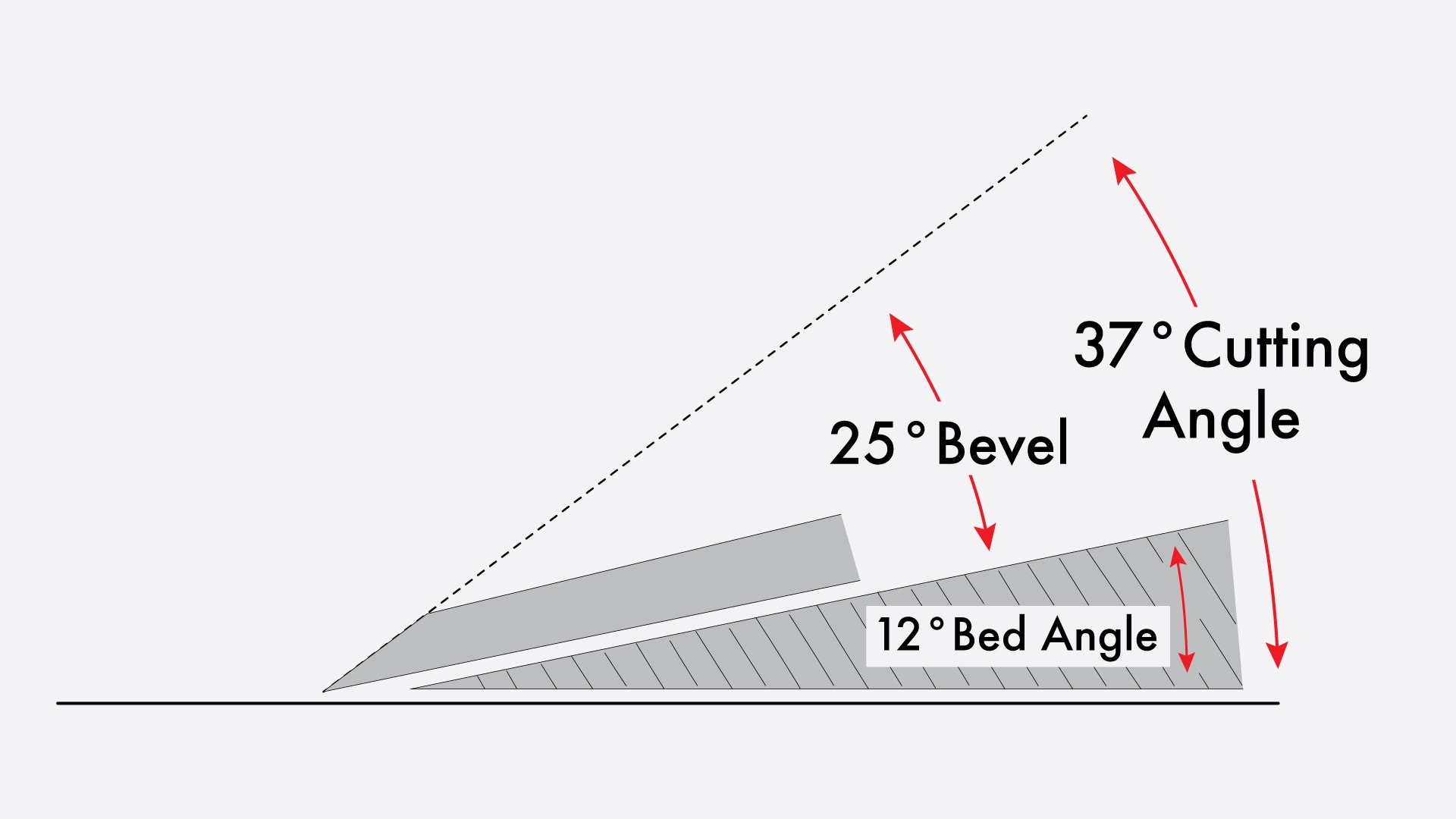

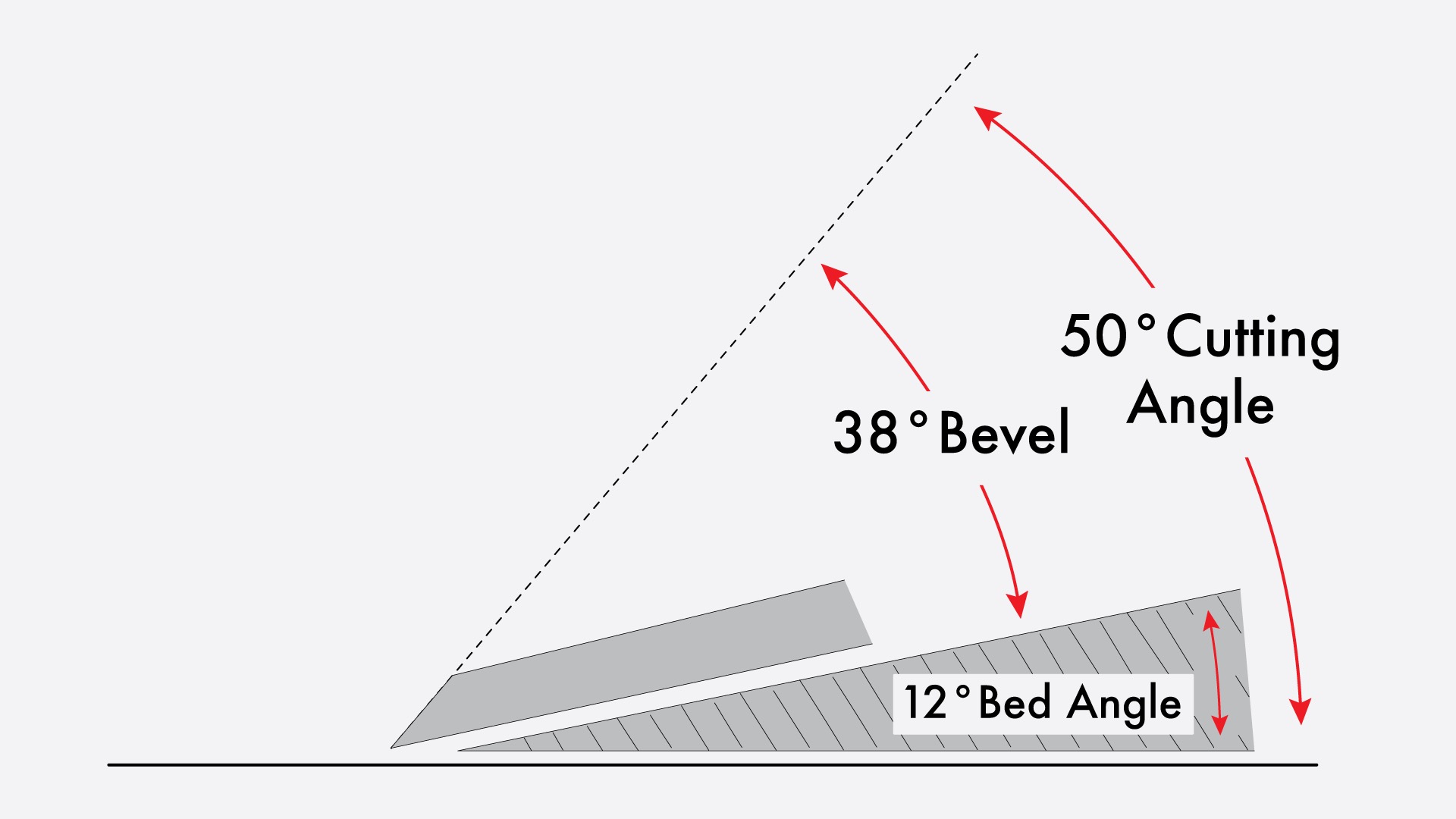

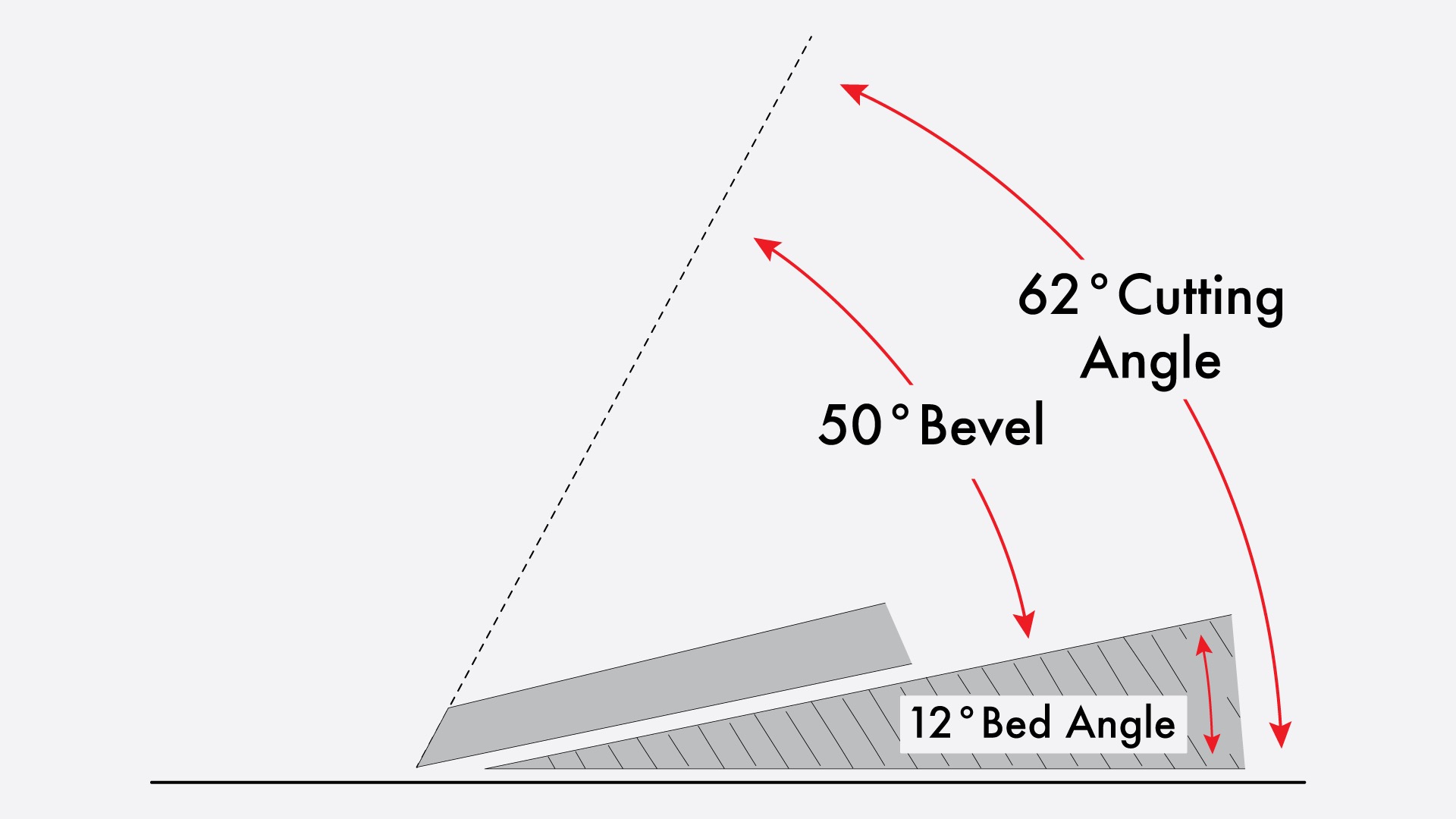

To figure out the effective cutting angle, add the bed angle of 12° to the bevel on the blade. For example, a 25° blade on the 12° bed will give you a 37° effective cutting angle.

The 25° Blade

MTC low angle planes are always supplied with a 25° blade which gives you an effective cutting angle of 37°. This bevel angle is perfect for shooting end grain - the short ends of your wood where you are cutting laterally across the grain. You can also use a low angle blade in a smoothing plane if you are working softer, flame patterned woods or a soft docile species like eastern white pine.

The 38° Blade

The 50° effective cutting angle is perfect for the general smoothing surfaces with calm grain. Old Stanley bevel down planes used to provide a 45° effective cutting angle so this isn’t far off. It’s a little steeper which gives you the confidence to plane most calm woods without worrying about tear out. More on tear out in a future blog!

The 50° blade

The 50° blade produces an effective cutting angle of 62°. This high cutting angle is ideal for smoothing figured timbers where tear out is a problem. Stripey woods like rosewoods and sapele have roey, interlocking grain which results the grain changing direction in parallel lines across the boards. This blade is the last stop before switching to a scraper.

What’s a woodworker to do?

It’s generally accepted that the lower the effective cutting angle, the better the finish will be. That said, some woods cannot handle low angles of attack and will tear out. The key is to use the right blade for the circumstance. If you can get away with a lower angle, then go for it.

I typically start low and work my way up the blades until I get a tear out-free surface. The beauty of a low angle plane is that you can change the angle you sharpen the blade at to achieve a different angle of attack. Even better, you can simply add a blade or two to your kit so that you can cover all the situations that come up when working in the shop. One plane and a couple extra blades is less expensive than three planes.

Enjoy your time in the shop!

Vic Tesolin & MTC Staffers